Bespoke ironmongery & hardware

Trusted by the Royal Family

The levels of bespoke design

This level is for basic requests and non-standard combinations of standard products.

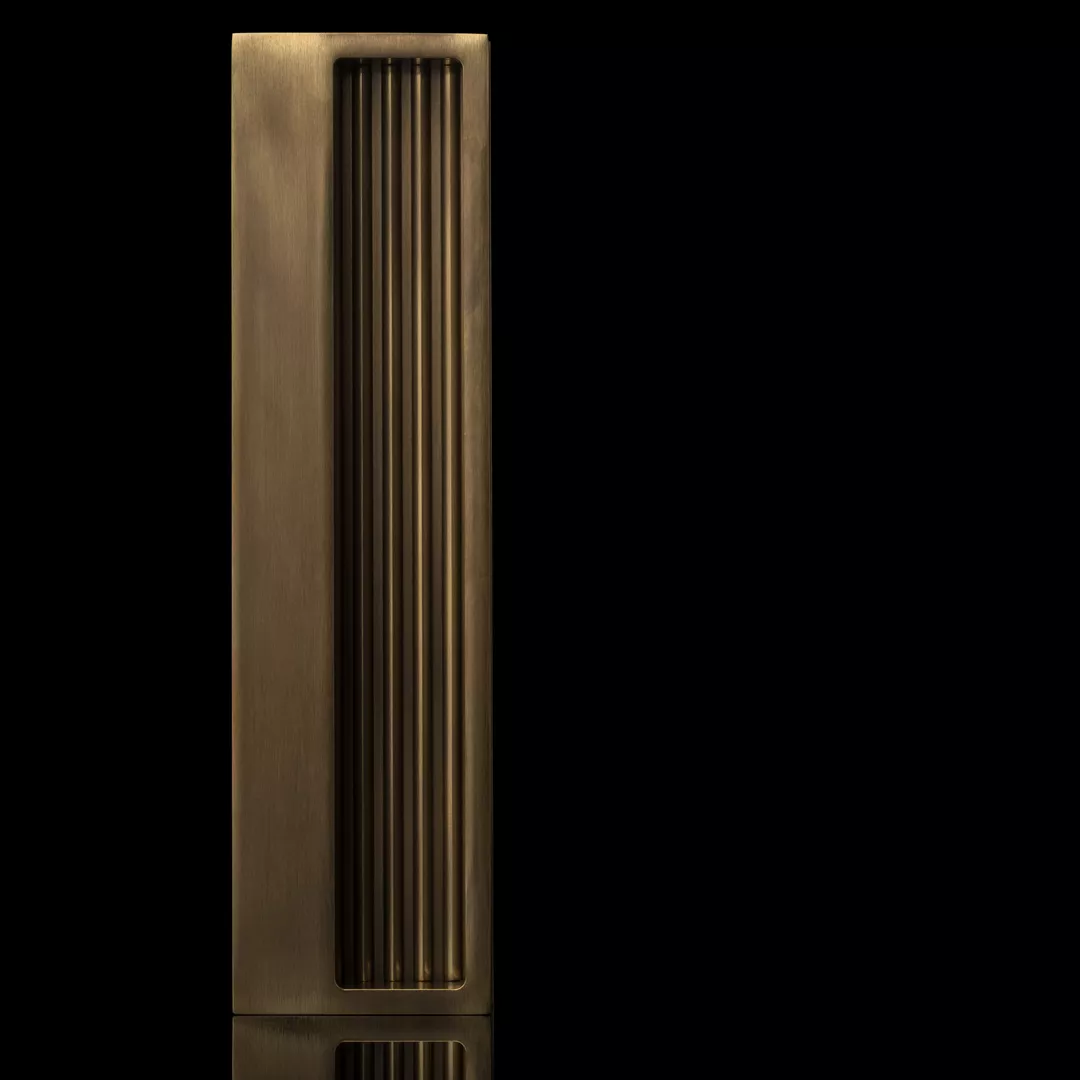

For example, a lever handle with a different style stock rose, extended strike plates or an edge pull in a bespoke length.